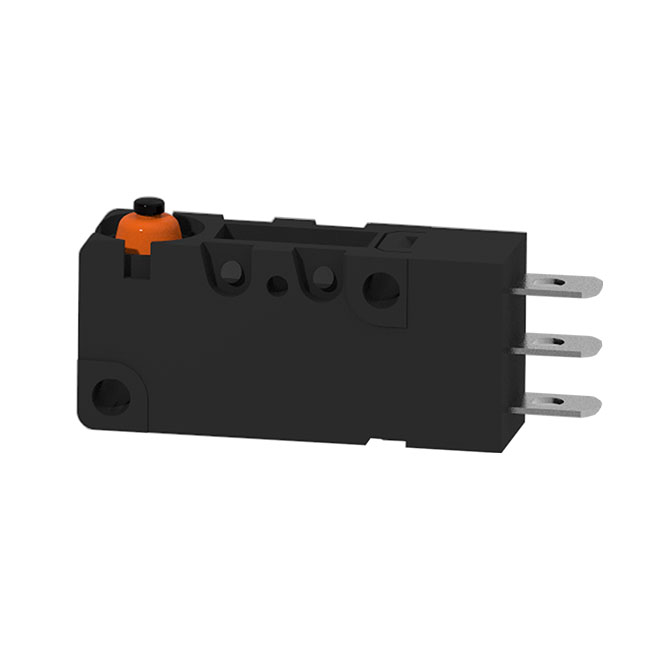

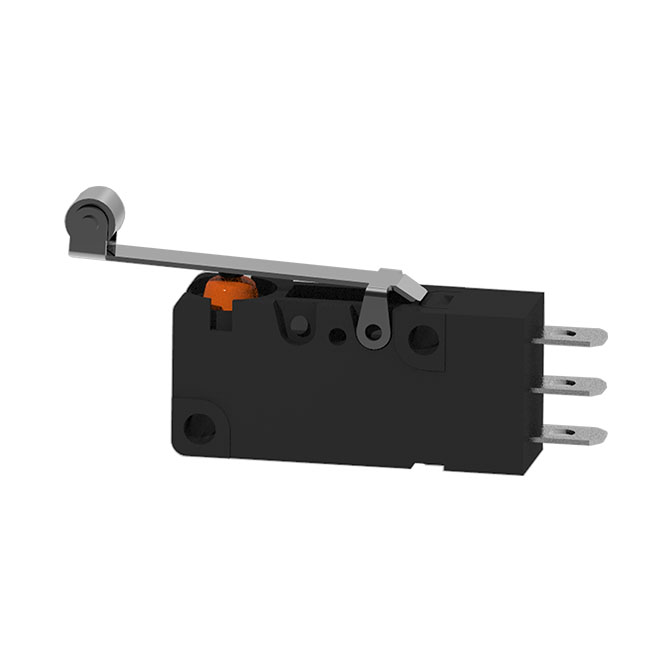

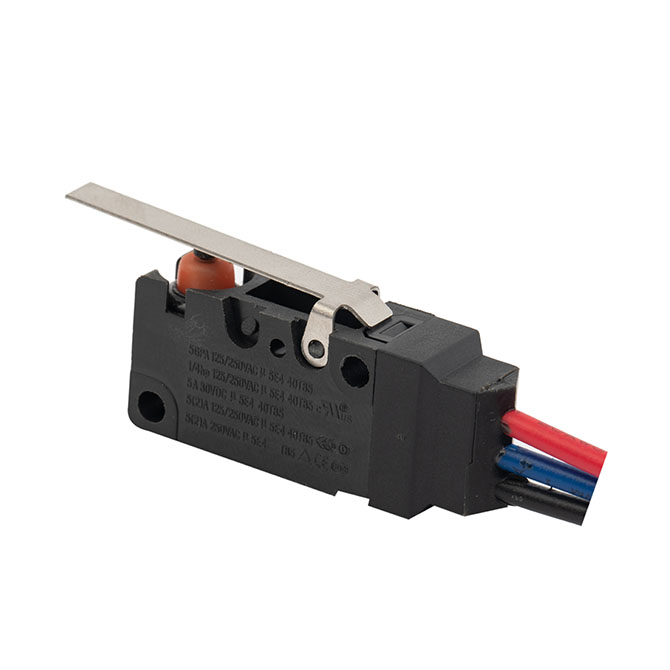

Characteristics and usage

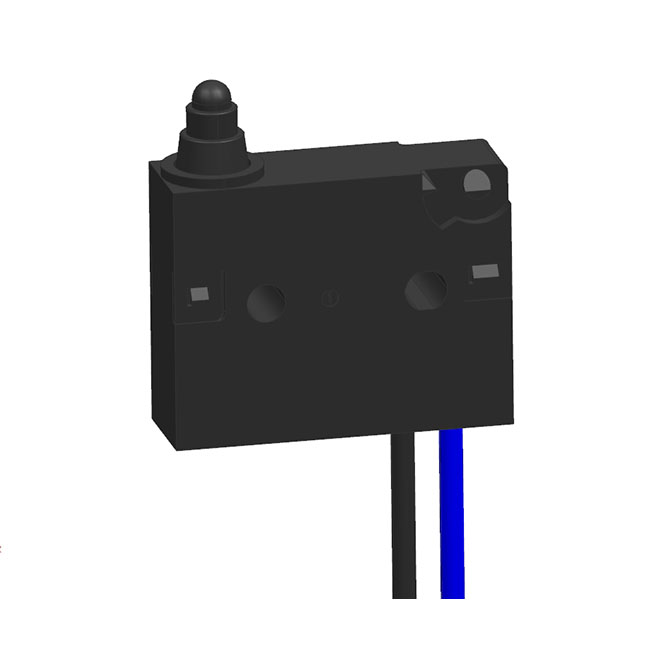

- 1. To be stably sealed by sealed rubber ring and epoxy resin. Can be used in wet or dusty places.

- 2. Provide solder terminal and wire terminal.

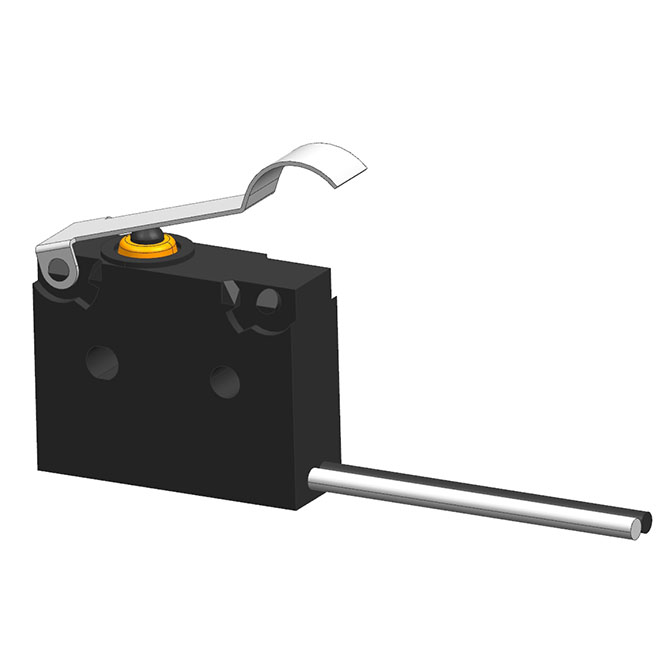

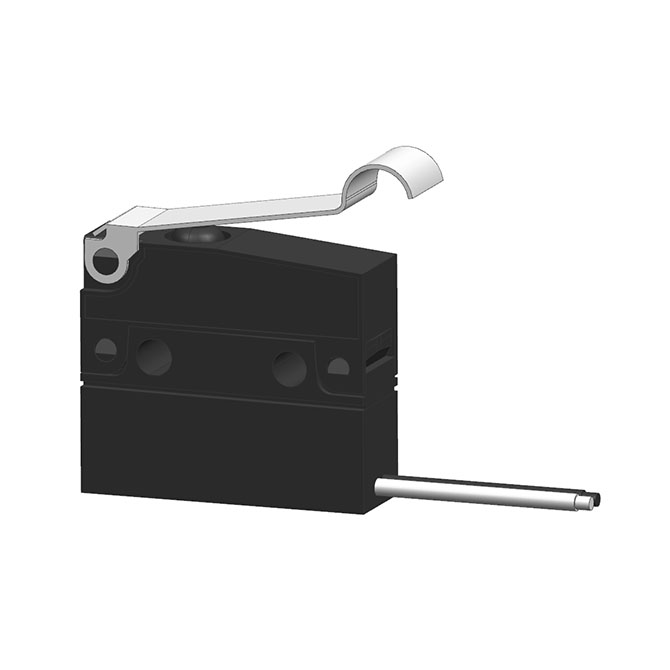

- 3. A variety of levers.

- 4. Can be used in environmental resistant requirements application such as automobile, agricultural machine, large home applicance, office equipment etc.

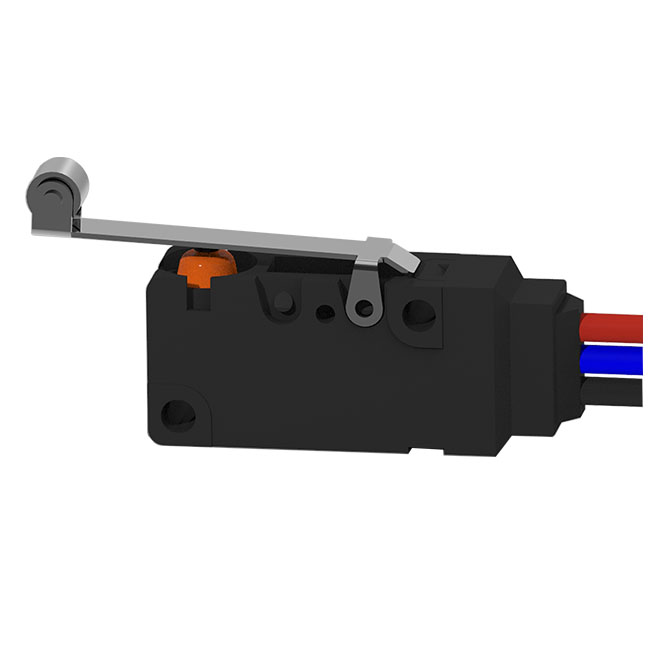

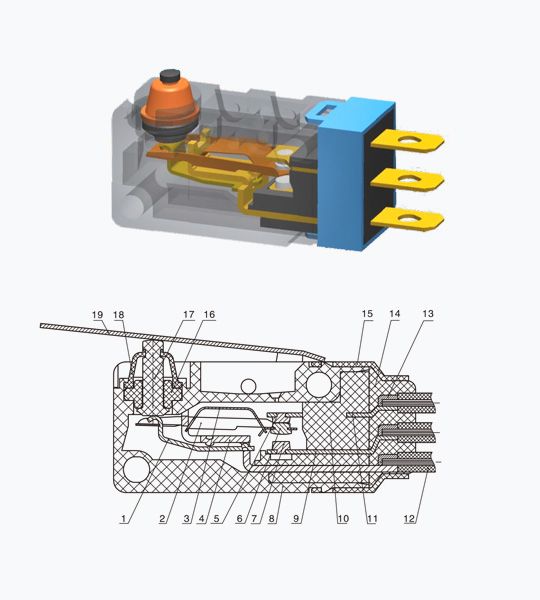

Internal configuration drawing

- 1. Lever

- 2. Moving piece

- 3. Spring sheet

- 4. Support

- 5. Contact

- 6. Contact

- 7. Contact

- 8. Case

- 9. Terminal

- 10. Fixed piece

- 11. Terminal

- 12. Wire

- 13. Soldering tin

- 14. Epoxy resin

- 15. Cover

- 16. Annulus

- 17. Plunger

- 18. Hermetic loop

- 19. lever

Technical characteristics

| Item | Value |

|---|---|

| Operating Speed | 0.1mm~1m/s (No lever) |

| Operating Frequency | Mechanical 60 cycles/min; Electrical 25 cycles/min |

| Insulation Resistance | ≥100mΩ(500VDC) |

| Contact Resistance | ≤30mΩ(Initial value) |

| Test Voltage - Between terminals of the same polarity | AC1000V, 50/60Hz, 1min |

| Test Voltage - Between current-carrying metal parts and ground(case), and between terminal and non-current-carrying metal parts | AC1500V, 50/60Hz, 1min |

| Vibration Resistance | 10~55Hz, 1.5mm double amplitude |

| Shock Resistance | Endurance: 1000m/s² (approx.100G) max Worng action: 300/s² (approx.30G) max |

| Electric shock proof protection degree | Ⅰ class |

| Case protection degree | IEC IP67(Except terminal part of terminal type) |

| Life | Mechanical≥1,000,000 cycles Electrical≥50,000 cycles |

| Safely Approvals | UL, CUL, ENEC, DEMKO, CE, CQC |

Various model combinations

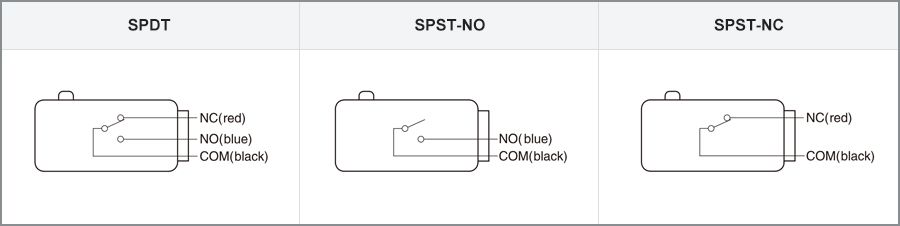

Circuit illustration